Opportunity

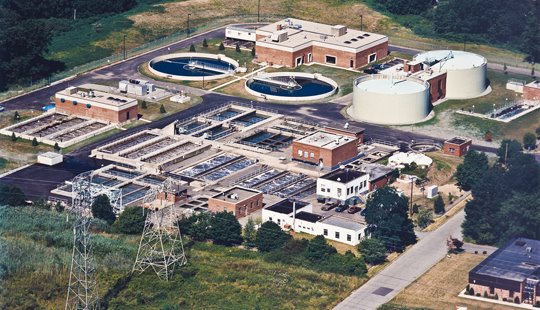

Originally constructed in 1938, the Water Pollution Control Facility of the Township of Livingston has been expanded and upgraded to meet the needs of the growing township. Its capacity was doubled in 1979, from 2 million gallons per day (MGD) to 4.2 MGD, and in 2000 it was further increased to 4.62 MGD.

The treatment process consists of primary clarification and a two-stage activated sludge process. The solids handling facilities include a primary and secondary sludge digester and dissolved air flotation sludge thickeners.

The facility produces an average of 40,000 cubic feet per day of digester gas. A portion of the gas is used to heat sludge or generate hot water, but about 21,000 cubic feet per day is flared off — an ongoing waste of energy and money.

Solution

In 2011, the Township retained Mott MacDonald to perform a study that would consider the feasibility of installing a combined heat and power (CHP) system. The system would use digester gas to generate electricity and hot water, and the power could be used to run plant equipment and provide hot water to heat both sludge and buildings.

Mott MacDonald evaluated historical data on biosolids and the production of digester gas, calculated theoretical gas production, and compared those figures with actual data.

We found that the facility’s on-site anaerobic digesters were capable of producing up to 60,000 cubic feet of digester gas per day. Once installed, a 150-kilowatt CHP system would be able to supply all the heat required by the digestion process, enough heat for the Advanced Treatment Building, and up to 86,400 kilowatt-hours of electricity per month — about a third of the facility’s average demand.

Total capital cost for the design and construction of the CHP system would be about $2.4 million, including equipment and installation, site preparation, engineering, and legal and permitting fees.

Outcome

Our study demonstrated that a CHP system at the facility would be technically, economically, and legally feasible. The project would provide an environmental benefit by reducing the facility’s overall carbon footprint, reducing air emissions and fulfilling the Township’s desire to implement green projects at the facility.

Mott MacDonald calculated that annual revenue for the CHP system would include power savings of almost $130,000 per year (at 12 cents per kilowatt-hour), natural gas savings of $8,000 per year, and maintenance savings for the sludge heating boiler of $11,200 per year. The expected payback period for design and construction of the system could be as little as 15 years.

We recommended that the project be pursued, and obtained a $450,000 grant for construction funding from the New Jersey Clean Energy Program.