Transforming rail on Manhattan's East Side

Project overview

Effective project management and innovative solutions to enhance commuter rail in a bustling city

Grand Central Terminal in Midtown Manhattan, with over 750,000 visitors per day, is one of two commuter rail stations serving New York City, the other being Penn Station.

With a growing concentration of jobs on the East Side of Manhattan, commuters from Long Island were faced with an increasingly congested commute via Penn Station and then by subway. As part of an overall regional plan, East Side Access – the first expansion of commuter rail in over 100 years – was moved forward from planning to reality.

Working without disruption in an underground environment within one of the world's busiest cities presented multiple challenges, including high-rise buildings with deep basements, 100-year-old cut-and-cover subway lines built by rival private railroads, water tunnels, and, in the case of Grand Central Terminal, a maze of high-pressure steam tunnels.

As part of the Program Management Consultant delivery team, we provided solutions to the engineering challenges and the project constraints by relying heavily on open communication, innovation, and collaboration with the Metropolitan Transportation Authority (MTA), other operating railroads, third-party stakeholders, and contractors. Developing this project-wide culture and building trust was the key to successfully delivering the East Side Access project.

Risk management and contract strategies

We oversaw 35 separate construction contracts, including pre-contract packaging and chairing the contract managing working group for developing 75 contract packages, both third-party and railroad force account contracts. These ranged from the $1.2 billion Manhattan tunnels construction package to a $2 million instrumentation installation contract in Queens.

Four underground excavation contracts were procured as requests for proposals which enabled negotiation between the MTA and the bidders. This was particularly helpful for the contracts covering soft ground tunnels in Queens, an extremely high-risk project. Through protracted negotiation sessions, risks were identified and risk-sharing mechanisms were established within the contracts.

One of the risks identified was how to manage the potential for compressed air interventions into the tunnel boring machine (TBM) cutterheads for tool maintenance. Working with the contractor, it was agreed that the contract would cover the first 800 manhours of interventions with pre-agreed rates for interventions in excess of this number. Clear guidelines were also established to define the durations of such interventions. During construction, no additional manhours were needed and the process was managed transparently.

A specialized approach was also used to manage ground risk on this contract. Rather than using a geotechnical baseline report, we baselined the contractors’ expected performance in the anticipated ground conditions. Any delay claims due to ground conditions had to be supported by comparing actual progress to the project schedule. Meeting with the contractor daily to review previous production and preview what was expected was critical to managing expectations. Ultimately, there were no differing site condition claims on this contract.

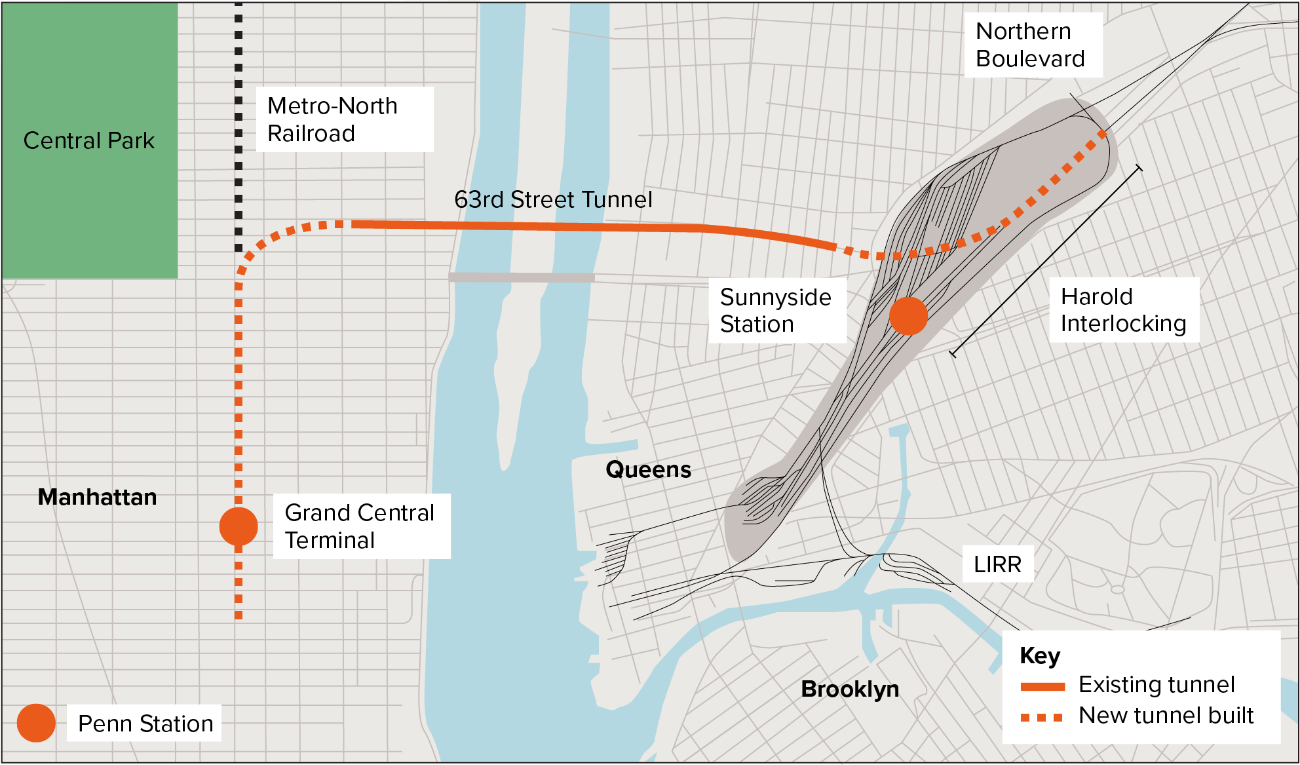

Underground connection to Queens

Just beyond the 63rd Street Tunnel in Queens is the Harold Interlocking and Sunnyside railyards, which include a 1.5-mile-long (2.4-km-long) rail junction that sees more than 800 trains per day, the busiest railroad interlocking in North America. As part of the East Side Access project, the junction required extensive upgrades to accommodate three new connection tracks to take trains from the Long Island Rail Road (LIRR) mainline into Grand Central.

To connect the LIRR mainline tracks in the Harold Interlocking to the existing 63rd Street Tunnel, two slurry TBMs, each 23 feet (23 m) in diameter, excavated four running tunnels for about 2 miles (3.2 km) using precast concrete segmental linings. These configurations were a first for the local workforce. Slurry TBMs offered greater control of ground movement, crucial for passing 30 feet (9 m) beneath the 60-mile-per-hour (96.6 km-per-hour) tracks in the Interlocking.

To connect these tunnels to the existing 63rd Street Tunnel, a sequential excavation mined tunnel 66 feet (20 m) wide through soft ground using sprayed concrete lining was excavated beneath Northern Boulevard. This 120-foot-long (36.6-meter-long) tunnel was one of the most technically challenging parts of the project, involving mining through piles supporting a five-track cut-and-cover subway box, the highway, and an elevated metro line.

The team developed a solution using ground freezing to create a frozen arch around the excavation under the subway box. Compensation grouting holes were drilled to manage any heave or settlement. The contractor successfully underpinned the elevated subway, completing the excavation in three years without major settlement or disruption to transportation above.

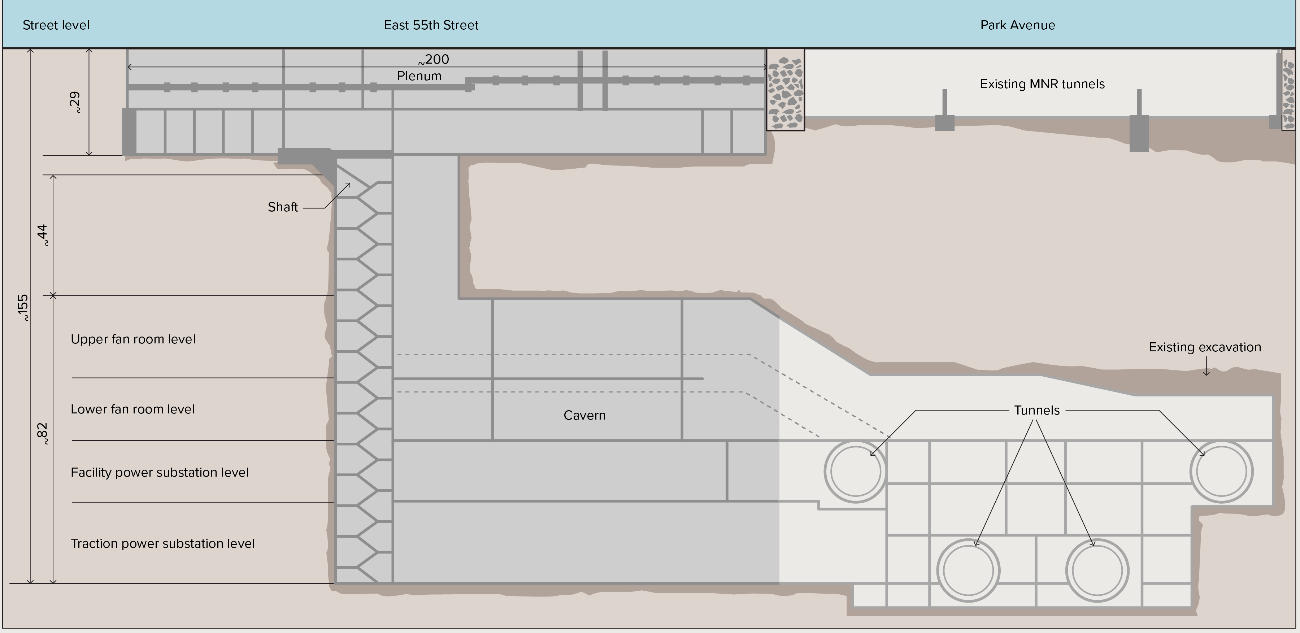

Tunnels take Manhattan

On the other side of the East River, the geology is drastically different from the soft ground of Queens. Excavating in the Manhattan Schist, which varies in strength from 68 to 275 megapascals (MPa), the contractor performed eight separate TBM drives ranging in length from 1,600 feet (487.7 m) to 1.5 miles (2.4 km), working out of a shaft in Queens at the east end of the existing 63rd Street Tunnel. Contractors built all the underground works in Manhattan by bringing all construction material through the tunnels and removing the muck through the same tunnels using conveyors.

From the end of the existing 63rd Street Tunnel, 7 miles (11.3 km) of new running tunnels were mined using hard rock TBMs. The contractor launched the TBMs in starter chambers made by enlarging part of the existing tunnels and mined two tunnels toward Grand Central Terminal 5 Wye, a vertical separation point where the running tunnels split into the upper- and lower-level drives.

From this point, four tunnels head south beneath Park Avenue. Shortly before entering the station caverns, there are crossover caverns at both the upper and lower levels. Once through the crossovers, the running tunnels bifurcate and four tunnels pass through the caverns on each level before the eight tunnels reunite to create four tunnels that run to 37th Street.

The contractor selected two hard-rock TBMs with a combination of rockbolts, mesh, and full-circle steel for the initial support. Less than 5% of the tunnel needed the full-circle ribs, and they were used in areas where the pillar between tunnels was less than 8 feet (2.4 m) to provide resistance to gripper loads. TBM production rates averaged 43 feet (13 m) per day.

A major challenge was relaunching the TBMs, as there was no shaft at the southern end, meaning that the TBMs had to reverse through the completed tunnels. The contractor removed segments from the cutterhead, creating sufficient clearance to enable one of the TBMs to reverse. For the other, a shielded TBM, required additional clearance that was provided by removing previously installed support elements from beneath a safety shield.

At times only one tunnel was available for mucking and material delivery to the active TBM and the relaunch operation, but there were a number of locations where the future running tunnels bifurcated and caverns had been excavated. Working with the contractor, the original design concept of enlarging around the wyes using drill and blast methods to create a TBM launch area was replaced by a process that entailed backfilling of a short portion of the previously mined tunnel with concrete and then mining the TBM on the new alignment using the concrete as support for the TBM grippers.

This method reduced excavation by 530,000 cubic feet (161,544 cubic meters) at each wye and crossover location, cutting TBM relaunch time from four months to six weeks, and also reduced the ventilation requirements for the completed tunnel leading to reduced power demand. With these wyes and crossovers located below the main interlocking for Grand Central Terminal, the alternative to blasting proved beneficial for numerous stakeholders and third parties.

Cavern sequencing

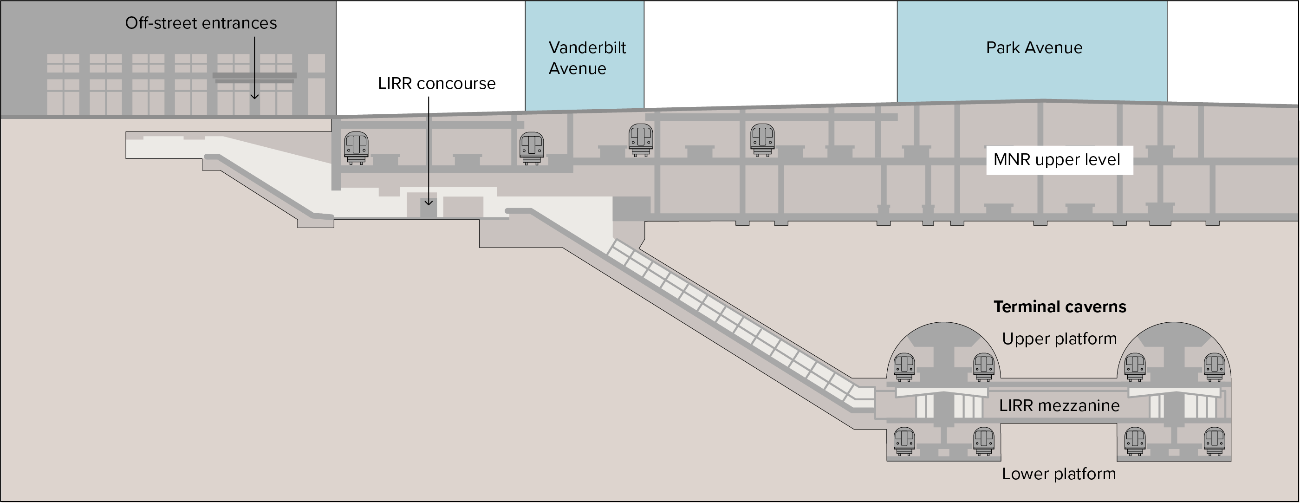

The new caverns designed for the East Side Access project are worthy of the iconic status of the station. The project includes a new 500,000-square-foot (152,400-square-meter) terminal within the existing Grand Central. To avoid blasting the entire project, the team pushed for the use of alternative excavation methods.

Contractors had to excavate the caverns plus the approach tunnels, five escalator shafts, and construct a concourse without a laydown area. The MTA’s Environmental Impact Statement stated there would be no additional truck traffic to Manhattan. Cavern construction overlapping with TBM tunneling on the Manhattan side of the project prevented access for cavern contractors to the worksite in Queens. This created a significant bottleneck for delivering supplies to the Grand Central Terminal’s cavern worksite.

The team secured a revision to the Environmental Impact Statement to accommodate concrete and explosives deliveries, but trucking muck through city streets remained restricted. The solution involved building trust with rail providers. For the concourse built at the lower level of Grand Central, the team had direct track access from a previous midday storage yard where they could maintain and operate two tracks through the construction period.

The railroad connected to a staging area about 9 miles (14.5 km) north of Grand Central. All supplies including site offices, reframing steel, glass, marble, and even portable toilets traveled in and out of the city on railcars. This required precise scheduling and coordination with contractors.

Even with concrete trucks allowed in the city, thanks to the Environmental Protection Agency (EPA) waiver, the team still faced the logistical challenges of the busy city streets surrounding Grand Central Station, and the lack of above ground access to underground works. Working with the Department of Transportation, the project delivery team would take possession of a parking lane, screen it off from the public, break out an access hatch in the sidewalk and create concrete drop pipes to reach the underground locations. These facilities allowed the trucks to deliver concrete, in some cases for up to three years.

However, this required proactive third-party management with Grand Central’s neighbors – well-known financial, commercial, and other institutions − as well as stakeholder coordination. At the same time, these drop pipes had to be shared by the project’s various contractors. The team maintained ample resources to ensure this ran as smoothly as possible.

The caverns are more than 1,200 feet (365.8 m) long, 66 feet (20.1 m) wide, and 66 feet (20.1 m) high, and house eight platform tracks. In some locations, these have been constructed with as little as 43 feet (13.1 m) of rock between the cavern arch and the operational tracks of Metro-North Rail above them.

Drill and blast excavation in Midtown Manhattan required extensive coordination with third parties and stakeholders. Working with Metro-North, as well as the New York City Fire Department, the team established a schedule between trains of 20-minute windows to blast up to five times a day.

Once the caverns started opening up, the project could sink shaft 5 to meet the TBM drives, providing new access to the underground for the workforce. The project delivery team reduced the number of blasts by driving the TBMs through the caverns. In the end, the contractor performed 2,365 blasts without causing a single train cancellation or delay, or any damage to Metro-North’s rail operations. Reusing the TBMs saved time, and the project continued to move forward into the next phases.

Innovative solutions in cavern construction

For the cavern walls, the team introduced sprayed concrete lining using hand spraying techniques instead of standard rebar against PVC membrane. This approach was necessary due to the complex shapes in the wye caverns.

Using sprayed concrete lining benefited the project schedule by allowing changes to the geometry of the wyes and using TBMs to mine them, eliminating the need for formwork, cutting out 20,000 cubic yards (18,288 cubic meters) of excavation, and providing more access space in the tunnel.

In the caverns a hybrid design was developed where vertical elements were either cast in place or shotcreted, while all the horizontal elements − what was needed to create the bilevels − were precast. This required bringing 6,000 pieces of precast, driven through the tunnels from Queens to Manhattan, on the back of trucks and installed in the caverns. All of the concrete work in both caverns was completed in nine months.

Transforming New York’s transit system

Extensive and detailed planning enabled this complex and stealthy tunneling to take place. From the extensive upgrade work in the Harold Interlocking, which eased conflicts between rail providers, to discreetly blasting below active rail operations in Midtown Manhattan, the project delivery team made sure no commuter’s daily journey to and from work experienced disruption related to the project.

For about sixty years, two generations, the New York transit system was essentially functioning in a status quo, with little action on expansion to meet the needs of a growing region. Today, we are lengthening a subway line, building the first quarter of what will be a new north-south trunk line running the length of Manhattan, and realizing a long-held dream of connecting the Long Island Rail Road to Grand Central Terminal. The conclusion of tunnel boring reminds us that New Yorkers remain capable of great achievements.Joseph J. Lhota

Former MTA Chairman

The project opened with limited service to Jamaica Station in Queens on January 25, 2023, and full service began on February 27, 2023. This megaproject provides new commuter rail service from Long Island and Queens to the east side of Manhattan in a new, eight-track terminal and concourse below Grand Central Terminal. Commuters from Long Island now have a one-seat ride to Grand Central and the upper east side of Manhattan.