Celebrating sporting excellence in Christchurch, New Zealand

Project overview

Building for the future with a new multi-use arena

In the aftermath of the devastating earthquakes that struck Christchurch in 2010 and 2011, large parts of the city were left in ruins. That included Lancaster Park in the central Canterbury district and the city’s historic home of rugby since 1914. Now, a new arena, One New Zealand Stadium at Te Kaha, is taking shape. It symbolises a shift from rebuilding to building for the future.

Te Kaha is the last in a series of government-funded anchor projects delivered as part of the earthquake recovery plan with the aim of rekindling local pride and stimulating wider redevelopment. It is capable of hosting motorsports, tennis, and boxing as well as rugby, with a crowd capacity of 30,000 in sports mode. For large concerts, with standing along with seated spectators, the capacity will be 37,300. One New Zealand Stadium at Te Kaha will also host conferences and business events.

We were engaged by lead contractor BESIX Watpac on behalf of Christchurch City Council to provide global stadium design expertise alongside Populous, an architectural practice specialising in venues. We worked with Christchurch-based companies including Powell Fenwick, Lewis Bradford, Holmes, and architects Warren and Mahoney.

From the outset, Te Kaha was a complex project with multiple key requirements. The project team were tasked with designing an arena that could accommodate a natural turf, would amplify internal acoustics for events, whilst minimising noise spill to neighbouring properties, consider carbon and sustainability in the design, construction and operation of the area, and ultimately be a signature attraction for the city.

Designing for pitch health

Christchurch winters are cold and for player and spectator comfort, the decision was taken to create a covered arena. Early in the concept design phase the team identified pitch health as the largest risk to the project. Maintaining a natural turf in top condition for competitive sports requires light, air and the right amount of water – neither too little nor too much.

These needs shaped the project. The arena has a fixed roof clad with translucent ethylene tetrafluoroethylene (ETFE) – an extremely thin plastic film that has high strength and excellent light transmission. ETFE would promote grass growth without artificial lighting.

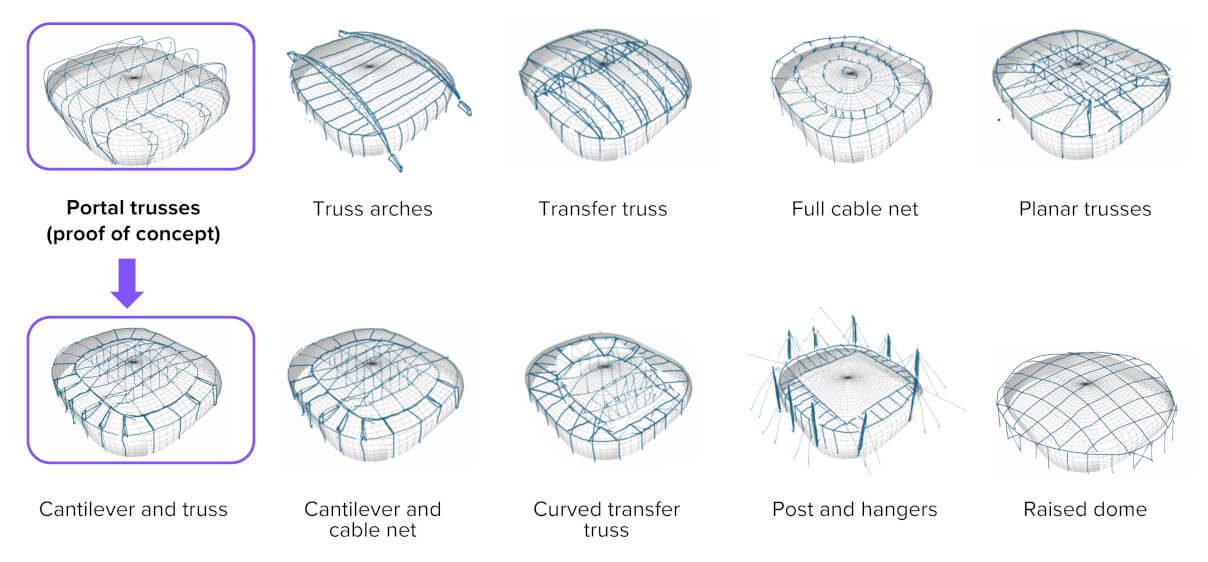

Multiple structural solutions for the roof and enclosure were modelled and evaluated. Alongside daylight and ventilation, the evaluation and selection process weighed cost, programme, the complexity of temporary works required to enable construction of the permanent structure, and visual impact.

Roof frame concepts

Structural optimisation

The preferred option was to span the arena with a cantilever and truss arrangement. The roof structure is supported by 40 primary columns which stand around the arena’s perimeter, organised in a radial pattern. Their right-angle joints are 32m above ground level and their horizontal cantilever arms point towards the arena’s centre. There are 12 lenticular or lens truss members which form the primary part of the roof. These span across the pitch itself in an orthogonal manner. The overall roof structure is optimised to be lightweight with an overall span of 175m in width by 211m in length.

An early decision was made to separate the roof and bowl structures due to their fundamentally different periods, functional requirements and behaviours under seismic action. The number of seismically separate bowl structures was also reduced to a total of four following liaison with the construction and programming team.

“The structural configuration was adjusted parametrically to achieve the optimal pitch science and acoustics outcomes, along with a focus on cost, constructability and programme,” notes Adrian Jones, project director for BESIX Watpac.

Developed design roof construction sequence and erection methodology

A resilient solution

With the devastating earthquake damage seen across Christchurch, a step change for the structural design of the arena was needed. The final design was assessed to consider levels of seismicity beyond the current code-defined maximum considered earthquake. Being conscious of an impending potential change in the defined seismicity of the region, the project team undertook a probabilistic seismic hazard assessment (PSHA) for the site. This unveiled that design actions for the period ranges of the arena bowl and roof structures could be between 15% and 45% greater than the existing code-defined approach.

To deliver a resilient arena, we adopted a mixture of Eccentric Braced Frames (EBF’s) with replaceable fuses and Buckling Restrained Braces (BRBs), which provide increased ductility, effectively serving as energy absorption devices. For the roof structure the project required the fabrication of 12-metre-long BRBs, the largest ever manufactured and tested in New Zealand. These were fabricated by Grayson Engineering, experts in heavy steel fabrication.

The substantial size of the BRBs presented unprecedented challenges. Previous prototypes required offshore testing, which was a time-consuming, costly, and environmentally demanding process. To find a more efficient solution, we collaborated with Holmes Solutions, recognised for its innovative testing capabilities developed after the Christchurch earthquakes. Holmes committed to building the necessary testing equipment locally, doubling testing capacity from 440 tons to an impressive 900 tons and increasing the size of the facility to accommodate items up to 20 metres long. This rigorous testing process, completed within an accelerated 16-week timeline, affirmed BRB performance and aligned with key objectives of utilising local resources and promoting sustainability - both crucial factors for the client.

Perfecting the sound

Acoustic performance was another key consideration. Although ETFE reflects much less noise than glass, earlier indoor arenas with ETFE roofs had suffered from high levels of acoustic reverberation. While that might add to the atmosphere of a sports event, it was undesirable for concerts and other performance events.

Anthony Calderone, technical director and Mott MacDonald’s building services and sciences design lead for the arena, explains: “To enhance sound quality, we had to consider various absorptive materials, including inflatable acoustic baffles, acoustic screens, and perforated ceiling and wall finishes. By importing 3D geometry into a specialist acoustic modelling software, we were able to generate precise reverberation calculations and model sound quality.”

This thorough assessment predicted a baseline reverberation time of 3.2 seconds at mid-frequency (vocals and lead instruments) and 4.8 seconds at 125Hz (bass guitar) for large concerts. For smaller concerts, with an acoustic curtain behind the stage, the reverberation times were predicted to be 2.0 seconds at mid-frequency and 3.3 seconds at 125Hz.

With the nearest residential property around 40m from the stadium façade, Christchurch City Council also had a focus on minimising noise spill to neighbouring properties. Different louvre and façade glazing configurations and locations were modelled to balance the impacts of noise spill, ventilation and capital cost.

The key challenge with a naturally ventilated arena is the need for openings, which create noise spill. Working to a tight budget and understanding that acoustic louvres can be up to three times more expensive than standard louvres, the team undertook careful evaluation of multiple options for both ventilation effectiveness and impact on the overall noise spill to nearby sensitive receivers.

The outcome was the adoption of acoustic louvres to the west façade and at high level within the seating bowl. This configuration would allow for a 104dB(A) concert with noise spill at the nearest apartment building of only 80dB(A) to align with district plan limits.

One New Zealand Stadium at Te Kaha is set to deliver an exceptional acoustic experience internally for any type of event, whilst limiting environmental impact as far as reasonably practicable.

Noise contours and the impact on neighbouring properties for various louvre configurations

Shared workflow

A shared workflow was established between the architectural, façade, structural and building sciences teams to coordinate models produced by each discipline, including the structure, pitch health, reverberation and noise spill, and airflow within the arena. This allowed for all critical elements to be considered simultaneously and compared through a multi criteria analysis.

We used our digital platform to communicate the results of modelling and analysis to the client and project stakeholders. The platform presents technical information via graphic dashboards that are highly intelligible. This enabled both clients, BESIX Westpac and Christchurch City Council, to take ownership of the decision-making process.

“Digital workflows enabled us to seamlessly collaborate with all project stakeholders, work more efficiently and design the best outcome for our client,” says Mott MacDonald technical director and roof package lead for the arena, Spencer Robinson. He adds: “We achieved significant savings in design and documentation time, but more importantly reduced roof tonnage and the associated cost and carbon of saved materials.”

Integrating design with sustainability

In 2019, Christchurch City Council declared a climate and ecological emergency. It set targets of achieving net zero total greenhouse gas emissions by 2045 (excluding methane). Carbon and sustainability were therefore key considerations throughout the project.

Following extensive workshops with the client and key stakeholders, we organised our design approach into 10 key strategies aimed at reducing both operational and embodied carbon. Throughout design and construction, these included:

- Pursuing solutions optimised for whole life carbon, sustainability, resilience, and cost performance

- Operational energy efficiency

- Use of passive ventilation to provide user comfort without the requirement for mechanical air handling

- Water efficiency, with a focus on minimising the use of potable water

- Specification of low carbon materials

- Minimising construction and operational waste

The project team meticulously assessed and achieved significant savings in the foundations, roof, and bowl structures, resulting in a predicted total embodied carbon of 95,100tCO2e – 16,600 tCO2e saved between concept design and detailed design. This achievement represents a 17% reduction over the baseline design.

One New Zealand Stadium at Te Kaha will open in April 2026. The project is the product of innovation and collaboration – and will stand as a testament to Christchurch’s resilience: a symbol of the city's strength and a beacon of hope for the future.

Total savings equivalent to:

316 cars off the road annually (based on 10,000km of average annual driving over 50 years)

7233 truckloads of concrete effectively removed from the project’s carbon footprint

Subscribe for exclusive updates

Receive our expert insights on issues that transform business, increase sustainability and improve lives.