Expert insights on issues that transform business, increase sustainability and improve lives

Topics that matter

Here’s a snapshot of what we’re thinking about. Explore these highlights or view the full library to dive deeper into the ideas shaping our work.

Meet some of our passionate problem-solvers, constructive creatives and inspiring innovators

Innovation in structural calculation improves global nuclear design efficiency

Application of a new structural calculator is streamlining design processes, enhancing optioneering capabilities and making Mott MacDonald more competitive in the expanding nuclear sector

Validated by regulators and international design code compliant, the cloud-based platform standardises workflows and improves design quality

After nine years of global development by structural engineers in Mott MacDonald’s nuclear team and professional software developers in our technology and data services team, the calculator is having a transformational impact on current projects

Streamlining nuclear design

A transformational new platform for structural design developed by Mott MacDonald is generating major savings in the nuclear sector, according to project director Desmond O’Malley and civil engineer Tom Holdsworth.

New clear solution

Development of the platform accelerates structural analysis and design checking without compromising on nuclear regulatory requirements. Generation of large global models that use finite element analysis (FEA) to describe structural behaviour under the expected load conditions is common practice, but a significant amount of engineering time is spent in post processing. Here everything in the design model is checked for different load cases to ensure that forces experienced by every single component meet design and regulatory requirements. For nuclear projects this is particularly challenging as the safety requirements add more layers of checking and assurance; for example, ensuring seismic resistance or understanding soil-structure interaction. There can also be a need to comply with various international design codes.

The structural calculator is revolutionising delivery in this post processing space. Previously, teams of structural engineers would analyse the FEA model outputs to carry out essential calculations that check critical parameters, such as deflections, axial loading and bending moments, comply with relevant design codes. Doing this for every beam, slab or column could take months. Streamlining this work was seen as essential and we looked to the latest digital technology and big data to find a solution to carrying out the calculations more efficiently.

Global validation

The first iterations of the structural calculator evolved from Mott MacDonald’s successful generic design assessment work for Hitachi-GE’s advanced boiling water reactor (ABWR) and China National Nuclear Corporation’s UKHPR1000 advanced pressurised water reactor technology. The nature of generic design assessments for new nuclear power stations means demonstrating the design effectiveness in a wide range of boundary conditions to the Office of Nuclear Regulation (ONR) in a rigid time frame. To do this, accelerating the post processing analysis was essential and the regulator had to be confident that the design processes were transparent, accurate and thorough.

Further validation and innovation came from working with France’s EDF on its next generation pressurised water reactor (EPR2). The client challenged us to provide visualisation tools that showed the effects of changes in a live environment. As a result, the structural calculator is now capable of creating visualisations that facilitate more collaborative working, helping clients and regulators to quickly and easily understand the design.

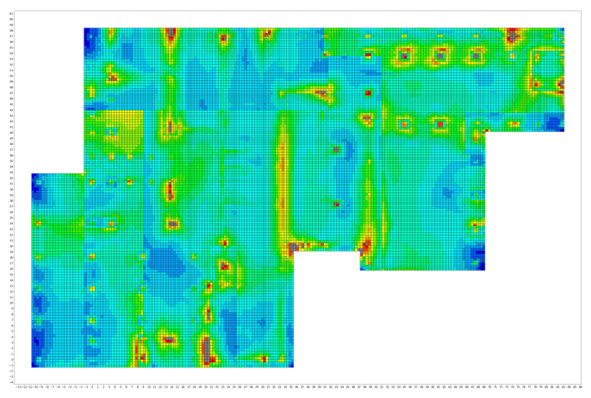

Optimisation visualisation for reinforcement design of a foundation slab for a nuclear research facility using the structural calculator. Red areas show reinforcement hot spots with other areas requiring less rebar.

Achieving 30% savings

Our work designing the MINERVA nuclear research facility in Belgium has been optimised by 30% through use of the structural calculator. The ability to quickly check the effects of changing different parameters by running them through the platform enabled the project team to immediately see the impact of various value engineering measures. The calculator made it possible to safely reduce the amount of reinforcement designed into the concrete base slab by 15% through analysis and adjusting the utilisation factor. This factor is a ratio of the predicted stress in the structure compared to the capacity provided by the reinforcement design. The visualisation tool allowed for observation of high utilisation hotspots, that ensured higher levels of reinforcement were maintained in these critical locations, without over designing the rest of the slab.

Without this validated proof, earlier methods would have maintained a more conservative level of reinforcement throughout the slab. Although this kind of optimisation can be done through conventional analysis, it would have taken months. Here, it took minutes.

Powerful proof

Early versions of the structural calculator were machine-based, but in 2024, its power was scaled-up by migrating to the cloud. Engagement with Mott MacDonald’s cyber security team, as well as with nuclear clients, was undertaken to ensure any data used and stored in the software was secure. Once assured that this was the case, the calculator was back-tested by running past project data through it.

The average time saving in civil and structural work was found to be 23%.

This streamlined efficiency empowers Mott MacDonald’s nuclear team to execute more projects and design iterations within the same timeframe. It improves optioneering capabilities and allows direct collaboration with colleagues, partners and clients to understand real-time design issues and achieve technical outcomes faster. Key learnings can easily be transferred between teams and projects, plus the use of a validated, standardised platform reduces the chance of human error. Another benefit of it being a centralised cloud-based platform is that updates, such as design code revisions, are consistently applied and cascaded to all users.

As a calculation delivery platform, the benefits of the structural calculator are so wide that it will bring advantages to other sectors too. It is also particularly well suited to critical infrastructure such as dams, hospitals, bridges and major buildings. Its transparent, validated format means it can be easily interrogated to test its capabilities to ensure client confidence ahead of adoption.

Daniel provides consulting and support services to business units, divisions or projects. He also supports Group level technology initiatives and handles relations with the principal vendors of design related technology.

-

Get in touch

This is a modal window that allows user to contact the person via a form. Escape key will close this modal window and take you to the page content. Tab through the rest of this modal window to navigate and populate the form. Press Enter key to submit the form once all fields have been correctly populated.

Sign-up here

Sign up for our Nuclear Know-How webinar series, designed for those who are solving nuclear’s biggest challenges. In February, March and April you can learn directly from Mott MacDonald specialists and clients as they share actionable approaches, new digital tools, and insights shaping the next generation of nuclear projects.

Register below to access all webinars and live discussions.

You might also be interested in

Why industry collaboration is vital to widen potential for nuclear powered data centres

Demand for data centres is growing and using nuclear reactors to power them is one way to ensure the increased energy consumption doesn’t affect the UK’s ability to deliver on net zero, while creating wider community benefits.

Designing decommissioning into the nuclear lifecycle to reduce costs

To meet the UK’s nuclear clean-up and infrastructure goals, the industry must shift from reactive cost control to proactive, data-led planning that integrates decommissioning from the outset.

Improving the viability of modern methods of construction for nuclear facilities

Discover how steel concrete composite structures are revolutionising modern construction methods for nuclear facilities, offering superior impact resistance and faster delivery. Learn about our research validating performance and building confidence in next-generation nuclear infrastructure.

Planning for flexibility critical to reducing nuclear costs

To lower lifecycle costs in the nuclear sector, facilities must be designed to anticipate future change, says Mott MacDonald technical director John Palmer.

Putting planning for whole asset life into nuclear design

From concept to decommissioning, we’re designing nuclear assets for performance not just construction.

Inclusive culture key to meeting demand for skilled nuclear specialists

Ahead of the annual Women in Nuclear conference, two women from Mott MacDonald’s nuclear team discuss how the business’ inclusive culture is helping to drive change and the challenges that still exist.

Collaborative design for a large-scale nuclear treatment plant

Our design expertise and seamless digital collaboration are ensuring the Sellafield site will continue to benefit from effluent treatment that reduces risk from high-hazard nuclear material.

A joined-up digital future for the NDA

The Nuclear Decommissioning Authority’s (NDA) digital vision supports more effective and informed decision-making by providing the appropriate information to the right people, improving how everyone works together and helping to undertake tasks more effectively.

Subscribe for exclusive updates

Receive our expert insights on issues that transform business, increase sustainability and improve lives.